Accelerates the localization of 12-inch large silicon wafers, and the expansion project of Xi'an ESWINN Silicon Industry Base starts

28 August 2023

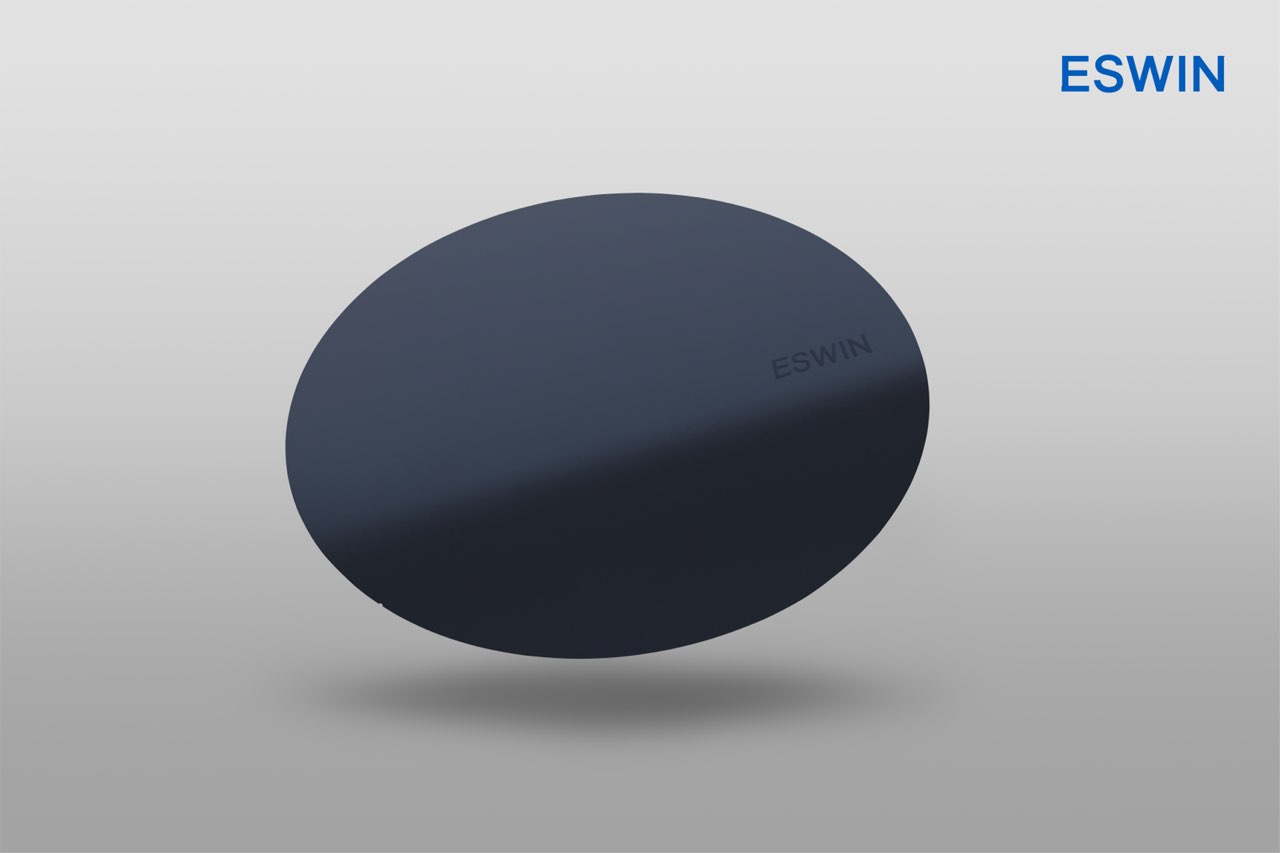

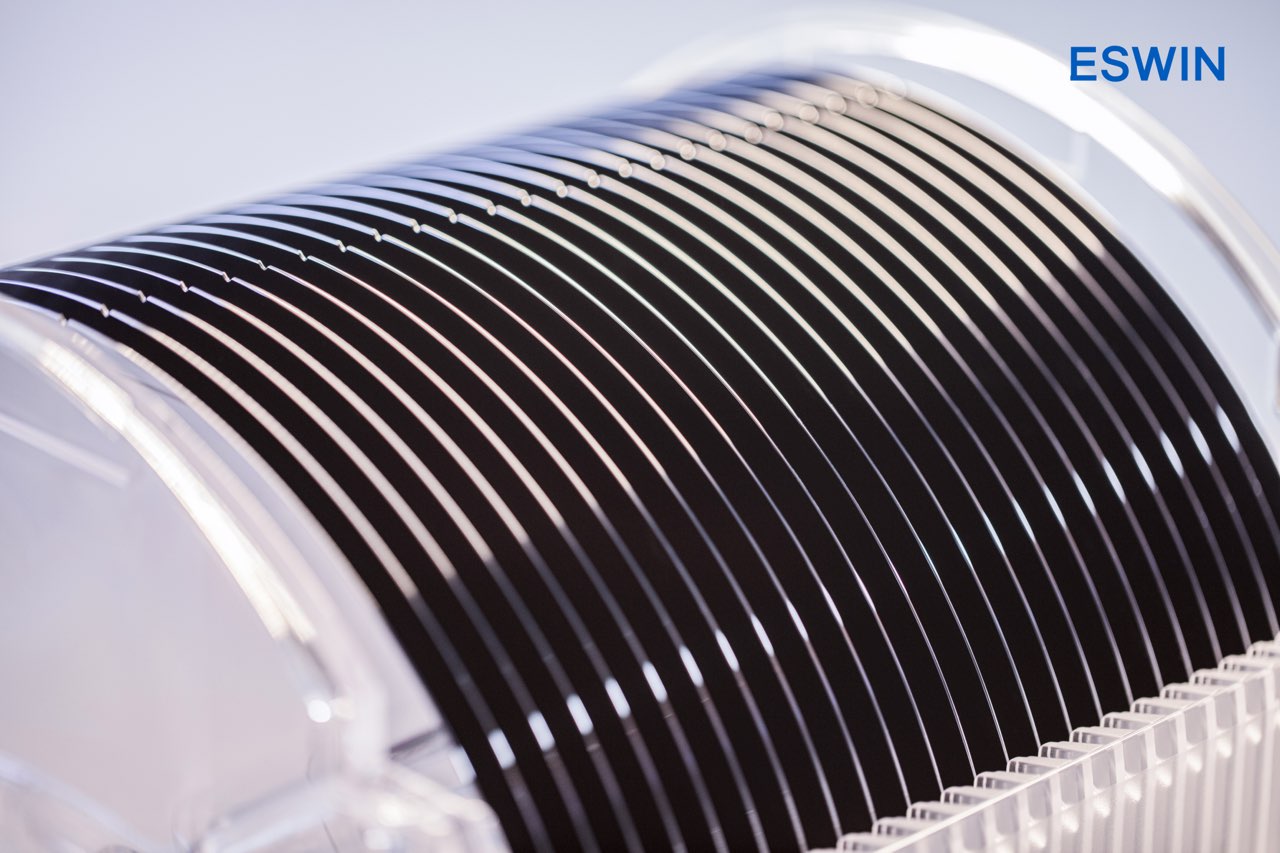

On June 14, the expansion project of Xi'an ESWINN Silicon Industry Base started in Xi'an High-tech Zone. ESWINN Silicon Industry Base currently has a 12-inch silicon wafer factory with a production capacity of 500,000 wafers per month, which has been put into operation in July 2020. Polished wafers and epitaxial wafers are provided by fabs at home and abroad. It is understood that the investment in this expansion project exceeds 11 billion yuan. After the expansion project is put into operation, it will further enhance the technical strength of my country's semiconductor silicon industry and strengthen the comprehensive competitiveness of the integrated circuit industry chain.

In the past two years, due to multiple factors, the production capacity of the integrated circuit industry has been tight, and the demand for large silicon wafers as upstream raw materials has continued to rise. However, the key raw materials of my country's integrated circuit industry are still in the early stage of development. The production capacity of silicon wafers is mainly concentrated in small sizes, and the self-sufficiency rate of large sizes is low. About 95% of mainstream 12-inch silicon wafers still rely on imports, and there is a huge gap in domestic production capacity. The larger the size of the silicon wafer, the more difficult it is to manufacture, and the stricter the requirements for technical indicators such as raw material purity, wafer flatness, surface particle number and metal residue.

In the past two years, due to multiple factors, the production capacity of the integrated circuit industry has been tight, and the demand for large silicon wafers as upstream raw materials has continued to rise. However, the key raw materials of my country's integrated circuit industry are still in the early stage of development. The production capacity of silicon wafers is mainly concentrated in small sizes, and the self-sufficiency rate of large sizes is low. About 95% of mainstream 12-inch silicon wafers still rely on imports, and there is a huge gap in domestic production capacity. The larger the size of the silicon wafer, the more difficult it is to manufacture, and the stricter the requirements for technical indicators such as raw material purity, wafer flatness, surface particle number and metal residue.

It is understood that the silicon wafer technical team of Xi'an ESWINN has rich experience in the semiconductor industry. The factory is equipped with world-class production testing equipment and advanced workshop and power system. The process technology has reached the level of the world's first echelon.

Reliable sources said that the Xi'an ESWINN silicon industrial base expansion project, which was signed and started this time, is positioned as a high-end product, and will be upgraded in terms of products, technology development, equipment, etc.: increase investment in core product research and development, further enrich product structure; adopt more advanced The advanced semiconductor technology route, the introduction of more cutting-edge manufacturing processes and technologies, and the optimization of the product process; the in-depth improvement of equipment design and selection, and the full introduction of automated production equipment will effectively improve efficiency and yield.

According to industry analysts, after the ESWINN silicon industry base is fully operational, its shipment volume is expected to become the first in China and enter the top six in the world, which can effectively alleviate the shortage of 12-inch silicon wafers in my country and further improve the technical level of my country's semiconductor silicon material industry. Improve the competitiveness of my country's integrated circuit industry chain.

Reliable sources said that the Xi'an ESWINN silicon industrial base expansion project, which was signed and started this time, is positioned as a high-end product, and will be upgraded in terms of products, technology development, equipment, etc.: increase investment in core product research and development, further enrich product structure; adopt more advanced The advanced semiconductor technology route, the introduction of more cutting-edge manufacturing processes and technologies, and the optimization of the product process; the in-depth improvement of equipment design and selection, and the full introduction of automated production equipment will effectively improve efficiency and yield.

According to industry analysts, after the ESWINN silicon industry base is fully operational, its shipment volume is expected to become the first in China and enter the top six in the world, which can effectively alleviate the shortage of 12-inch silicon wafers in my country and further improve the technical level of my country's semiconductor silicon material industry. Improve the competitiveness of my country's integrated circuit industry chain.